Victor Haugen

Member

Hi all

I am new to this forum and I have a few questions.

I have a F700 that was purchased in early 2002 and I have identified the fork as a Super Fatty DL, disc spesific - 80mm. However, looking at the Cannondale Catalogue, the bike is most likely a 2001 model. A little bit strange; the serial number is LG which is supposed to be a july 2000 model, but the CAAD4 frames did not appear on a F700 until 2001 if I am right (?). Anyway, now I am trying to do a Headshock service for the first time, by replacing the O-rings and the oil.

When I de-assembled the damper I saw that something made of hard plastic had broken and been crushed into pieces:

Then I found this part in the HD166 seal kit as shown in the photo below, which I believe is the piece that somehow has been broken and disintegrated during the years:

So if I understand it correctly, is this how it should be put together (?):

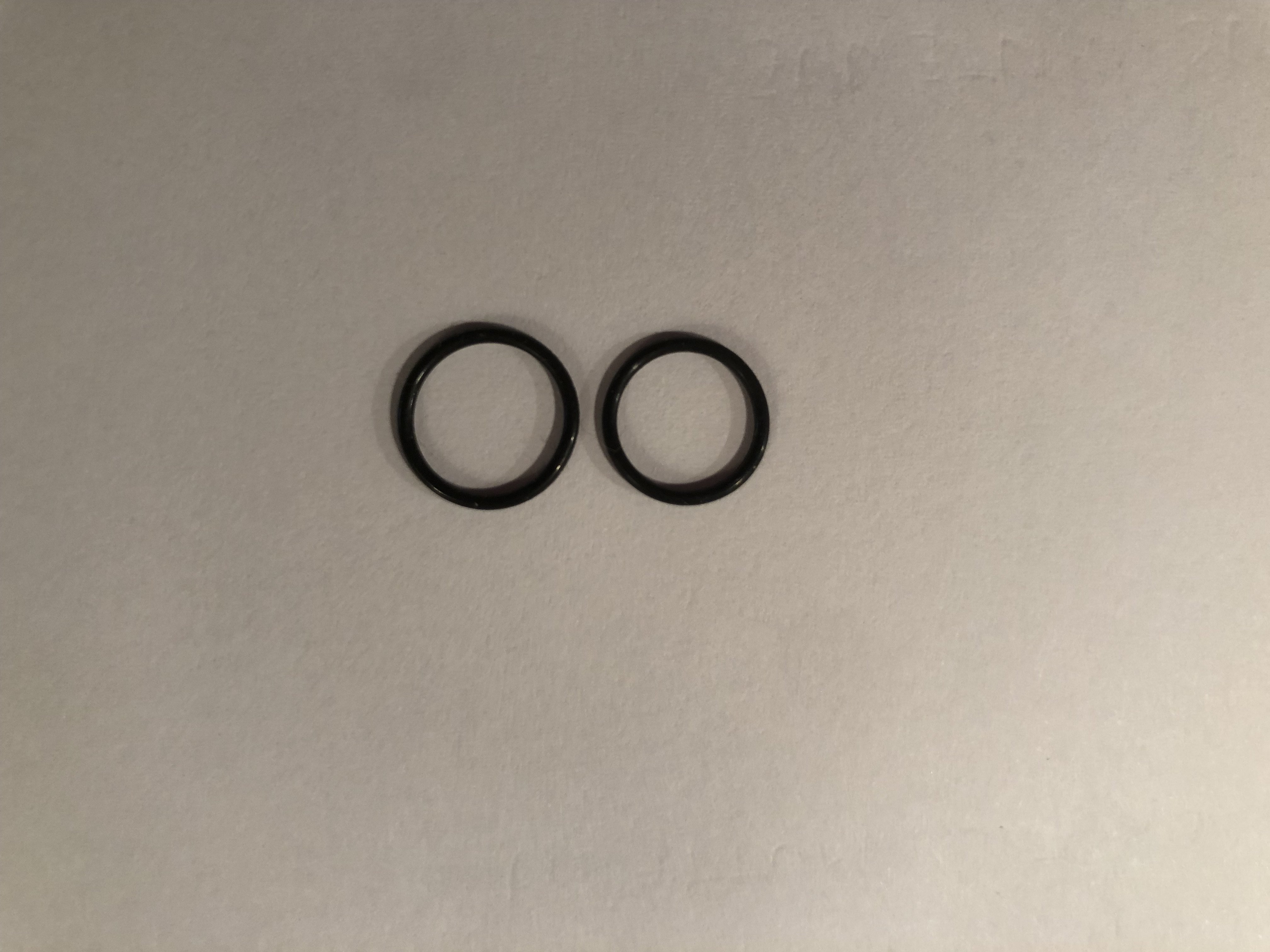

And then next question, I discovered a smal O-ring that was loosely attached (with some grease or oil) to the tip of the metal shaft:

However, I can't figure out where this O-ring should be attached. I tried to put it onto the plastic shaft but the O-ring is bigger than the shaft so it doesn't seem to be the right place and it doesn't seem to have a logical function:

Is there anyone who knows where this O-ring should be attached ?

The HD166 seal kit contains a similar O-ring but it's slightly smaller....however the original O-ring seems to be in good condition still, so I might be able to re-use it.

Victor

I am new to this forum and I have a few questions.

I have a F700 that was purchased in early 2002 and I have identified the fork as a Super Fatty DL, disc spesific - 80mm. However, looking at the Cannondale Catalogue, the bike is most likely a 2001 model. A little bit strange; the serial number is LG which is supposed to be a july 2000 model, but the CAAD4 frames did not appear on a F700 until 2001 if I am right (?). Anyway, now I am trying to do a Headshock service for the first time, by replacing the O-rings and the oil.

When I de-assembled the damper I saw that something made of hard plastic had broken and been crushed into pieces:

Then I found this part in the HD166 seal kit as shown in the photo below, which I believe is the piece that somehow has been broken and disintegrated during the years:

So if I understand it correctly, is this how it should be put together (?):

And then next question, I discovered a smal O-ring that was loosely attached (with some grease or oil) to the tip of the metal shaft:

However, I can't figure out where this O-ring should be attached. I tried to put it onto the plastic shaft but the O-ring is bigger than the shaft so it doesn't seem to be the right place and it doesn't seem to have a logical function:

Is there anyone who knows where this O-ring should be attached ?

The HD166 seal kit contains a similar O-ring but it's slightly smaller....however the original O-ring seems to be in good condition still, so I might be able to re-use it.

Victor

Last edited: