Nico

Well-Known Member

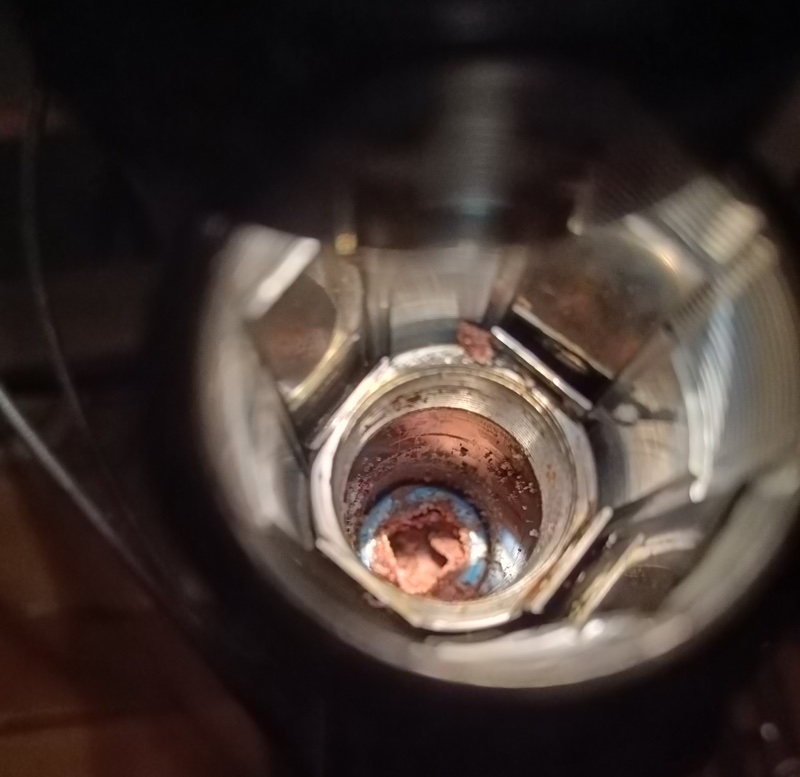

Took out the damper from my Killer V 800 (98 model).

I expected to find an elastomer that was just so much compressed that it had no life in it anymore.

What I found was a tube full of small bits of perished elastomer.

I cannot get this stuff out without contaminating the needle bearings so I will take out the bottom plug.

But first I have to finish another rebuild before I will continue working on this one.

More on this situation as the information becomes available.

I expected to find an elastomer that was just so much compressed that it had no life in it anymore.

What I found was a tube full of small bits of perished elastomer.

I cannot get this stuff out without contaminating the needle bearings so I will take out the bottom plug.

But first I have to finish another rebuild before I will continue working on this one.

More on this situation as the information becomes available.