Improve Part

New Member

Hi, guys.

I'm a new member, but maybe some people known the new brand in vintage Cannondale community. yes, we are Improve Part team, we produced some vintage parts of Cannondale and hope to supply more parts.

It's appreciate to know Brian who contacted me to join the forums, he told me that in here all of people who into vintage Cannondale too. I focused on MTB parts, didn't realize there are many demand of road bike part too.

Get down to business, we plan to produce some part that many people are looking for, but before producing I need you guys' suggestion of the part, and the data that I cannot measure.

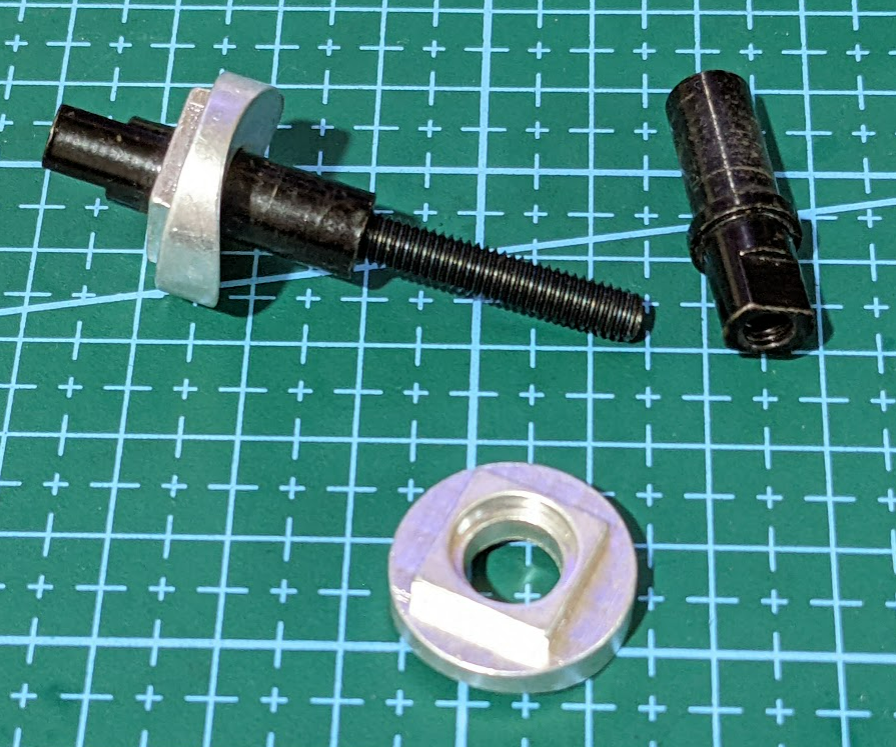

The first data: would you guys help me to measure diameter of frame downtube, I need to make the down side arc of washers fixing frame perfect. I don't know whether there are many kinds of standard in vintage road Cannondale.

The second data: would you guys help me to measure the diameter of hole where the part mounted on.

About the suggestions, I want to know whether you guys prefer to make the shaft with titanium, or still make it with steel? if you have more suggestion, please let me know.

BTW: my English is suck, hope I describe the part correct.

I'm a new member, but maybe some people known the new brand in vintage Cannondale community. yes, we are Improve Part team, we produced some vintage parts of Cannondale and hope to supply more parts.

It's appreciate to know Brian who contacted me to join the forums, he told me that in here all of people who into vintage Cannondale too. I focused on MTB parts, didn't realize there are many demand of road bike part too.

Get down to business, we plan to produce some part that many people are looking for, but before producing I need you guys' suggestion of the part, and the data that I cannot measure.

The first data: would you guys help me to measure diameter of frame downtube, I need to make the down side arc of washers fixing frame perfect. I don't know whether there are many kinds of standard in vintage road Cannondale.

The second data: would you guys help me to measure the diameter of hole where the part mounted on.

About the suggestions, I want to know whether you guys prefer to make the shaft with titanium, or still make it with steel? if you have more suggestion, please let me know.

BTW: my English is suck, hope I describe the part correct.